PROJECT OVERVIEW

Metal Garage

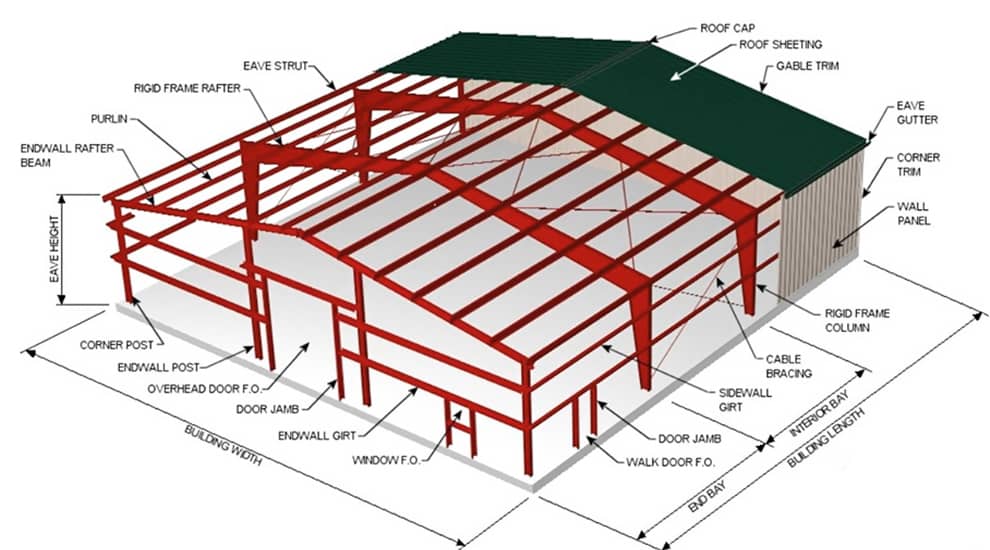

Metal garage has features of high fire resistance, strong corrosion resistance. Metal garage is mainly refers to the main bearing component is composed of steel. Including the steel columns, steel beam, steel structure, steel roof truss.Each component using welds, bolts or rivets to connect.

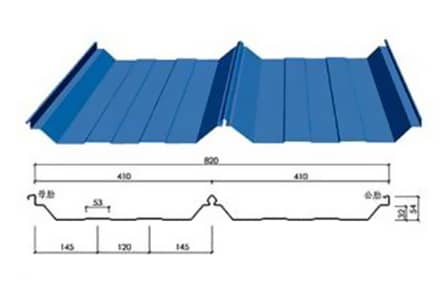

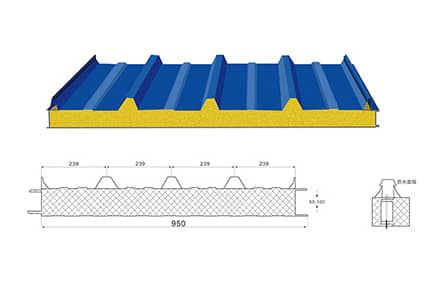

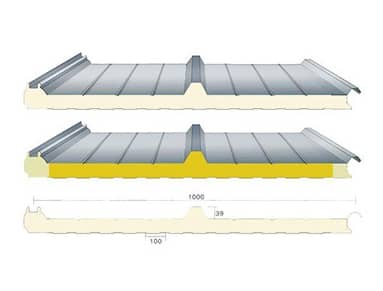

The roof and wall can be made of composite panel or veneer. Galvanized sheet metal can prevent rust and corrosion. The use of self-tapping screw can make the connection between the plates more closely, to prevent leakage. You can also use composite panel for roof and wall. The sandwich is polystyrene, glass fiber, rock wool, polyurethane. They have good thermal insulation, heat insulation, fire-retardant. The wall of the Metal garage maintenance also can use brick wall. The cost of a brick wall is higher than galvanized steel roof and wall.

SPECIFICATION

| Items | Specification | |

|---|---|---|

| Main Steel Frame | Column | Q235, Q355 Welded H Section Steel |

| Beam | Q235, Q355 Welded H Section Steel | |

| Secondary Frame | Purlin | Q235 C and Z purlin |

| Knee brace | Q235 Angle Steel | |

| Tie Rod | Q235 Circular Steel Pipe | |

| Brace | Q235 Round Bar | |

| Vertical and Horizontal Support | Q235 Angle Steel, Round Bar or Steel Pipe | |

| Maintenance system | Roof Panel | EPS Sandwich Panel / Glass Fiber Sandwich Panel /Rock Wool Sandwich Panel /Pu Sandwich Panel /Steel Sheet |

| Wall Panel | Sandwich Panel / Corrugated Steel Sheet | |

| Accessories | Window | Aluminiumn Alloy Window / PVC Window / Sandwich Panel Window |

| Door | Sliding Sandwich Panel Door / Rolling Metal Door | |

| Rainspout | PVC | |

| Live load on Roof | In 120kg/Sqm (Color steel panel surrounded) | |

| Wind Resistance Grade | 12 Grades | |

| Earthquake-resistance | 8 Grades | |

| Structure Usage | Up to 50 years | |

| Finishing Options | Vast array of colors and textures available | |

| Paint Options | Alkyd paiting, two primary painting, two finish painting(Primer, Medium paint, top coat, epoxy zinc etc.) Or Galvanized. | |

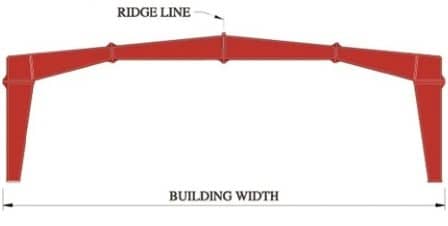

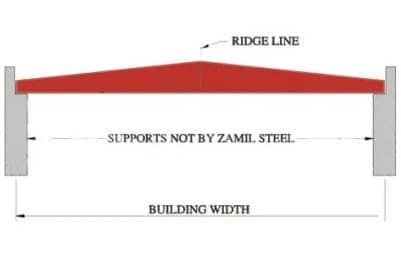

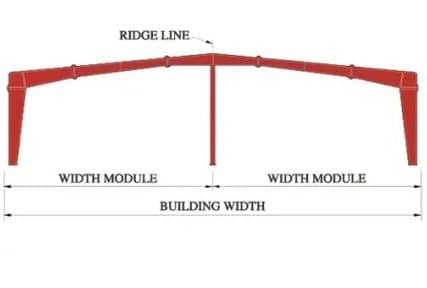

Clear Span

Building without interior columns -maximum practical width = 90m

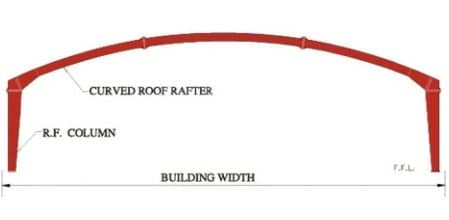

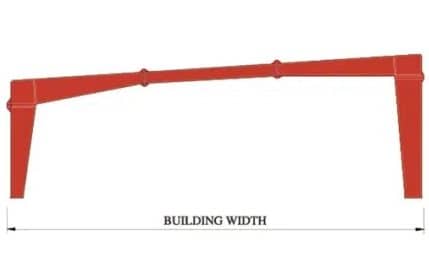

Clear-Span (Arched)

Arched Clear-Span -maximum practical width = 90m

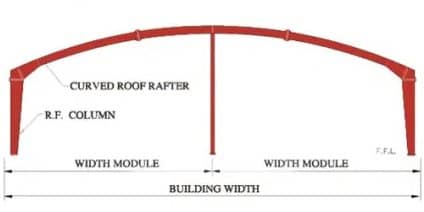

Multi-Span (Arched) AMS-1

Building with one interior column- maximum

practical module width = 70m

More multi-spans are possible

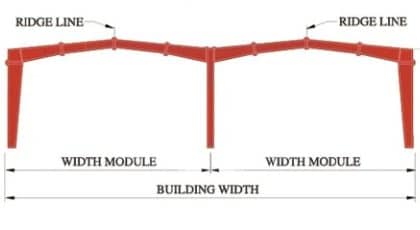

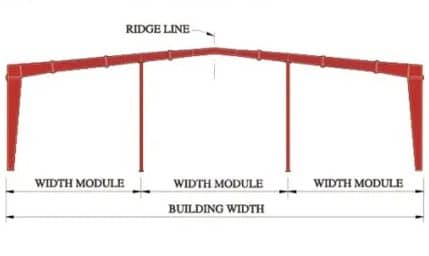

Multi Gable

Maximum practical module width = 80m

More multi-spans are possible

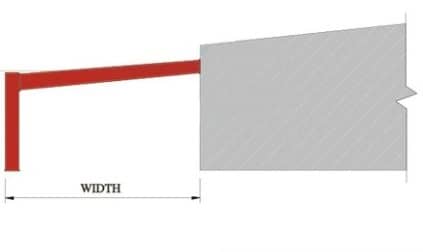

Lean-To

Maximum practical width = 24m

Lean-To

Maximum practical width = 24m

Multi-Span 1

Building with one interior column –

maximum practical module width = 70m

Multi-Span(Arched) AMS-1

Building with one interior column –

maximum practical module width = 70m

More multi-spans are possible

Multi-Span 1

Building with one interior column –

maximum practical module width = 70m

Multi Gable

Maximum practical module width = 80m

More multi-spans are possible

1.Primary Framing

Main steel frame is mainly composed of steel beams, steel columns, steel trusses and other components made of section steel and steel plate, and adopts rust removal and anti-rust process such as shot blasting, painting and galvanizing. Welding, bolts or rivets are usually used to connect each member or component.

JUHE’s pre-engineered metal garage is custom-designed to meet your exact requirements. The most common primary framing systems are shown below. Practically any frame geometry is possible. Consult JUHE for your specific requirements.

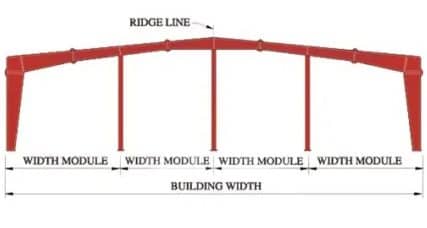

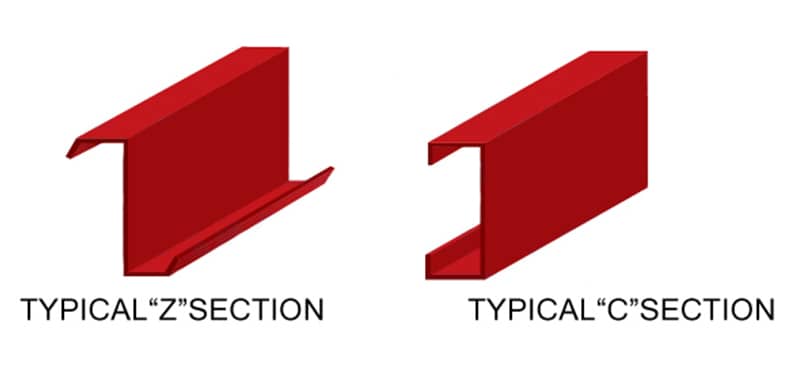

2.Secondary Framing (Bracing, Z and C section purlin)

Purlin, tie bar and bracing are secondary structural members used to support the wall and roof cladding.

Secondary members as purlin, tie bar, column bracing and horizontal bracing connect the main frame and help in resisting part of the longitudinal loads that are applied on the building such as wind and earthquake loads.

Steel purlin is available in high grade steel conforming to GB/T 2518-2008, Q235B/Q345B Grade or equivalent, available in 1.8 mm. 2.0 mm, 2.2 mm, 2.5 mm and 3.0 mm thickness. The purlin come with a galvanized sheet.

Column bracing is a connecting member set between two adjacent columns to ensure the overall stability of the building structure, improve lateral stiffness and transfer longitudinal horizontal force. Column bracing will be round steel or angle steel according to the building need.

3.Roof and wall cladding system

JUHE offers a complete line of Roof and wall steel sheet, sandwich panel, and their related accessories, steel cover, trims, eave gutter, curved eave cover, wall flashing for a wide range of building applications.Variety of profiles, base metal, metal substrates and coatings for its sheet. The metal sheet are used as roof and wall panels, interior roof and partition panel, etc.

Steel sheet, its base sheet is usually be galvanized sheet or aluminium zinc sheet with organic coating. It has the advantages of good corrosion resistance, bright color, beautiful appearance, convenient processing and forming, and has the original strength of the steel plate and low cost.

The thickness of steel sheet usually be 0.3mm-0.7mm and used in different building and requirement.

Sandwich panel is composite insulation panel made by two sides steel sheet and heat insulated core material through binder (or foam). The core can be EPS (polystyrene ), fiberglass wool, rock glass wool and PU (polyurethane), thickness 50mm, 60mm, 75mm, 100mm, 150mm, 200mm, etc.

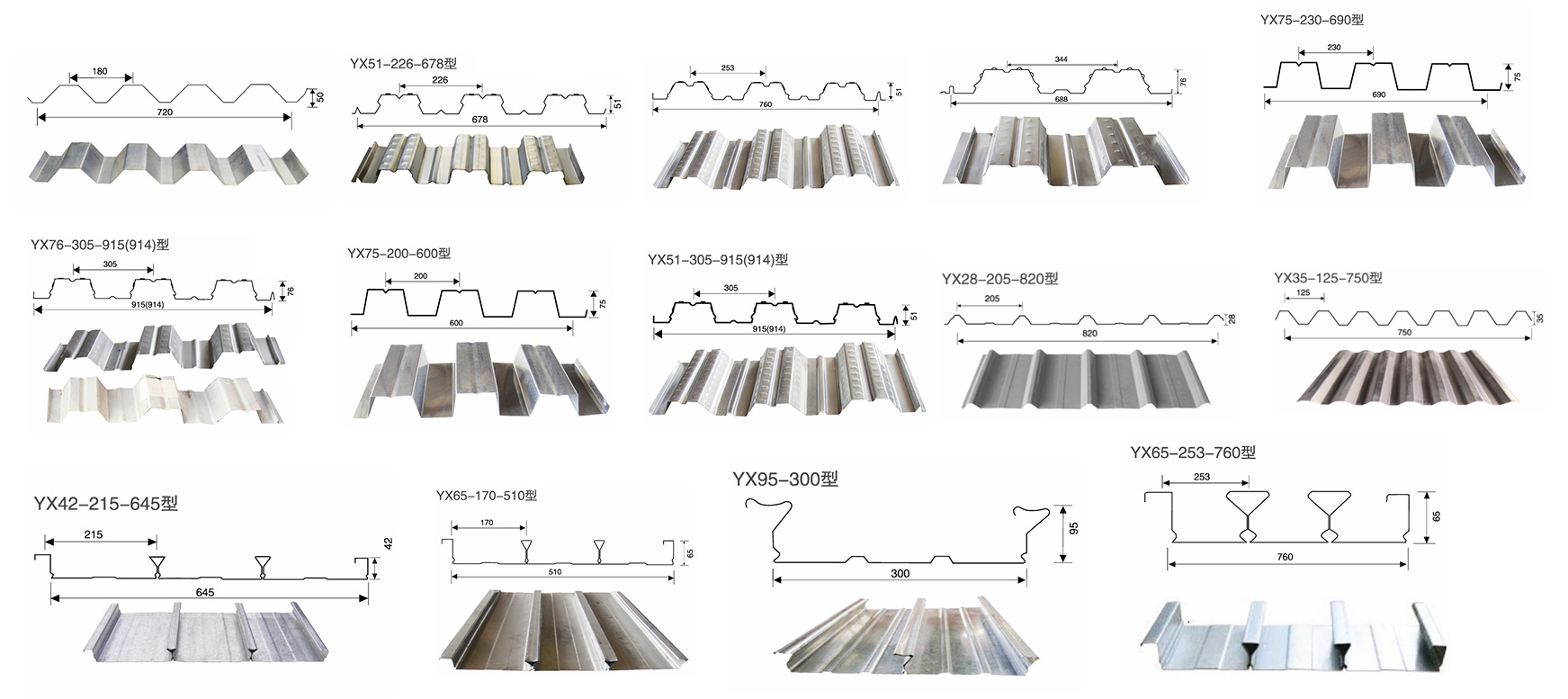

4.Steel Decking Floor

The pressed steel plates supporting the floor concrete are called profiled plates, also called floor bearing board.

The steel decking board are widely used in multi-storey buildings such as power plant, exhibition hall, steel structure workshop,metal garage, cement warehouse, steel structure office, airport terminal, railway station, stadium, concert hall, grand theater, large supermarket, logistics center, Olympic venues and sports venues and other steel structure buildings.

It can adapt to the main steel structure rapid construction requirements, can provide a firm platform in a short time, and can take flow repetitive construction operation, laid a number of floors decking board, and pouring concrete slab.

Advantages:

(1) Free to design architectural drawings for you;

(2) Features: Fast and flexible to assemble, safe, thermal and noise insulation, water proof and fire prevention;

(3) Cost-effective: Fast and easy installation greatly shorten the construction time which reduce the costs;

(4) Durability: The whole structure is easy in maintenance, which can be used for more than 50 years;

(5) Perfect design: Perfect design completely avoids leaks and water seepage. Meanwhile, it’s also in line with the national level of fire prevention;

(6) Carrying capacity: can resists the impact of strong wind and seismic performance and bears heavy snow loads.

MORE CHOICES

Why Choose Us to offer metal garage

(1) We have a group of professional engineers, most of whom has more than 10 years experiences in architecture field. our company has got a various of experiences in design, manufacture, installation and so on. The work staff have excellent skills. Some of them had helped customers to install the metal garage around the world.

(2) We will offer one stop service. construction drawing,calculation sheet will be offered to help you get construction permit. Foundation design could be free made if you need. We could make 3D drawings to show the view. What’s more, Installation drawings will be offered and Steel structure column,beams will be marked number on it to help you install.

(3) We will send you extra bolts,purlins,panels incase any damage when install.

(4) Efficiency is our pursuit. Every inquiry ,emails will be replied immediately. Every questions will be paid high attention.

(5) We also have possessed more than 40 sets of large precise and domestically advanced processing equipments, including large gantry planing machines, automatic submerged arc welding machines, assembling machines, slitters, shot blasting machines and soon.

(6) We will offer details packing list for every container when load so it will be easier to unload.

(7) “Moral personality decides product quality.” is our guarantee to the products. “Customers come first.” is our everlasting pursuit. Believe your choose, we’ll give you a satisfied answer.

Live shooting

Construction Site

Other Products

Cold Storage

Walk In Freezer Storage

Cold Room for vegetables/seafood

Cold storage supporting facilities

Take the next step

We have a passion for unconventional solutions that bring your vision to life.

Get in Touch

Dedicated to helping clients solve their most products challenging products and technology issues. Please complete the form below, and our sales team will be in touch with you shortly. Receive regular industry updates and product design tips straight to your inbox.

- +86 15563533037

- +86 15563533037

- +86 15563533037

- lottiechen@juhesteel.com