IS A PROFESSIONAL STRUCTURAL STEEL FABRICATORS

We have professional sales, design, procurement, production, scheduling and installation teams.Provide customers with one-stop service from design to installation.

AN INDUSTRY LEADING DESIGN-STRUCTURAL STEEL FABRICATORS

WITH UNMATCHED EXPERIENCE & EXPERTISE

we have a very strict seven systems, The improvement of the system is to ensure our production capacity and production the high quality and after-sales service are completed to better serve customers.Our professional, qualified team of engineers, project managers, superintendents, and architects is capable of designing and building the most demanding project anywhere in the country. We pride ourselves in offering the best, most cost-effective single-source solutions and adding value to every project.

Superior project delivery

Turnkey solutions resulting in responsibility, integrated design, and accelerated schedule.As a result, our customers reap the benefits of total integration. Our team of design-build construction experts effectively gain an understanding of each client’s business and analyze the key components to reduce exposure and provide the very best value.

Team strength

- Exquisite production technology

Feeding→ pickling and washing→ solvent→ drying→ hot dip galvanizing→internal and external blowing→ label rolling and marking→ passivation → inspection → packaging

- Huge production scale

The company has production workshop covers an area of more than 40,000 square meters, annual output of 600,000 tons of pickling production line 2 and annual output of 100,000 tons of cold rolled plate production line 3.

Perfect Inspection Equipment

The company is the first in the industry to pass the international ISO9001 quality system certification, With the State Administration of quality supervision of the special equipment production and operation license.An industry leading design-structural steel fabricators.

It adopts international or national standards, and has a set of testing methods,such as powerful chemical performance testing, process performance testing, eddy current testing, hydraulic testing and high-precision carbon and sulfur analysis. The product quality is reliable and the performance is stable.

Excellent technical team

The company has more than 400 employees, including more than 80 core sales team, 55 senior engineers, 21 professional testing personnel, 22 management personnel.

Our company will conduct regular training for them to ensure our production capacity and quality, so as to better serve customers.A strong high standard team, will break out a strong force!

KEY SERVICES

JUHE can service all of your structural steel fabricators needs. Our shops fabrication capabilities are not limited to what we have done in the past; we thrive on bringing your ideas on paper to life.

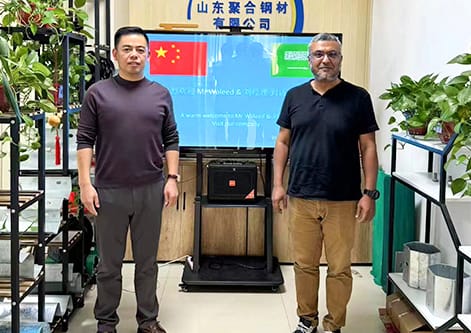

CUSTOMER VISIT

As a world-class structural steel fabricators,After entering the international market for more than ten years, our products have been sold to North America, Asia, Africa, Europe, South America, Oceaniaand sales amount continues to increase. Up to this year, the sales amount has reached to 2 billion with annual export volume of more than 20,000 tons steel structure and 50,000 square meters prefab house.With good products and services, we have been unanimously recognized by customers so to grab a larger market share.

We will be anywhere you need us!

Take the next step

We have a passion for unconventional solutions that bring your vision to life.

Get in Touch

Dedicated to helping clients solve their most products challenging products and technology issues. Please complete the form below, and our sales team will be in touch with you shortly. Receive regular industry updates and product design tips straight to your inbox.

- +86 15563533037

- +86 15563533037

- +86 15563533037

- lottiechen@juhesteel.com